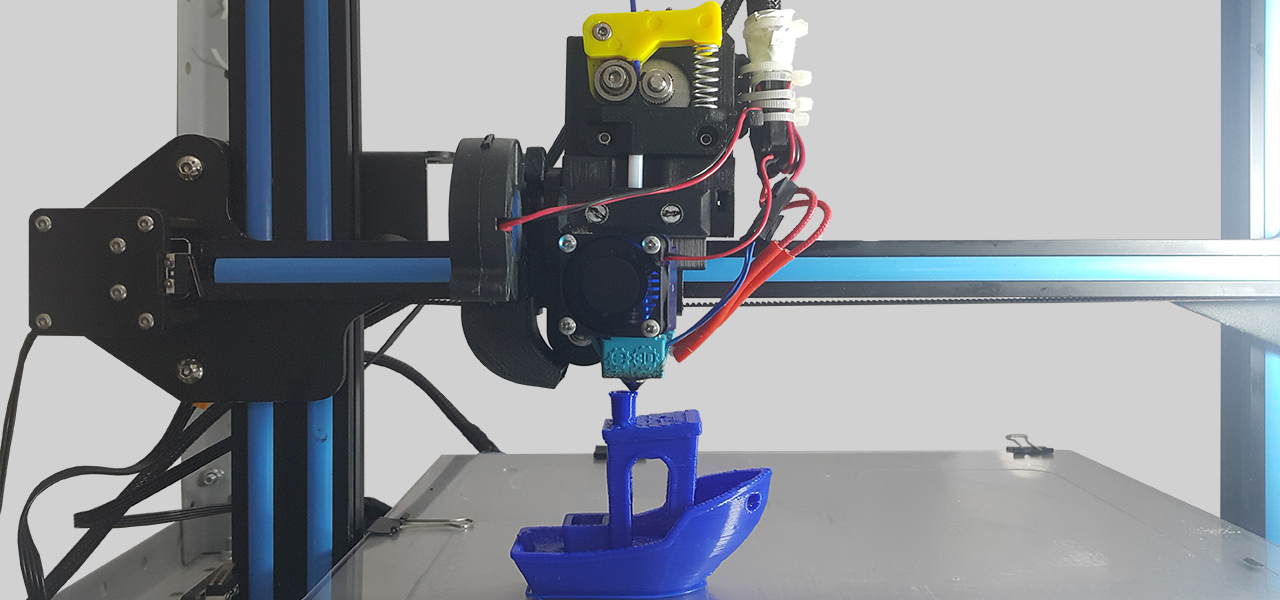

The Creality CR-10 bowden extruder is great when printing with ordinary filaments like PLA, PETG and ABS. The only maintenance is changing the drive gear when it is used.

When it comes to tough composite or flex filaments it is a whole different story. I was struggling to get nice prints with carbon PET (ultra-tough abrasive filament) and with wood (needs constant pressure in the nozzle). The stock bowden extruder was just not up to the task. I tried with high-end Capricorn tube, but still – there were drive gear drops now and then that just wouldn’t allow to leave the printer alone. It needed surveillance and manual help in order to assure constant printing flow and avoid clogging. The most difficult filament though was the flex. You can not help it by pushing with hand – it is elastic.

So, I started looking for options to install a direct extruder on the Creality CR-10 printer.

Direct drive extruder options for Creality CR-10

The commercial options to get direct extruder on CR-10 are expensive upgrades in the 100+ EUR range.

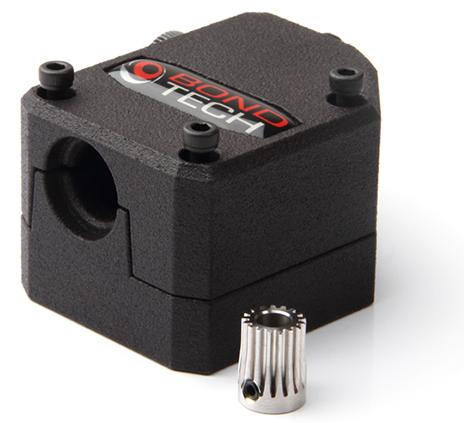

The Bondtech BMG extruder seems the most reliable and versatile option. It can be used as bowden or direct. It is adapted to directly mount on the e3d v6 hotend. This seems to be a mechanics masterpiece, but comes with a price tag of 100 $ (roughly 90 EUR). And then you have to buy a stepper – ideally a pancake one. It is another 20 to 50 bucks – depending on the quality. Other than scarifying your kids’ Christmas gifts, the implementation will require tuning in Merlin to adapt to the new gear ratio.

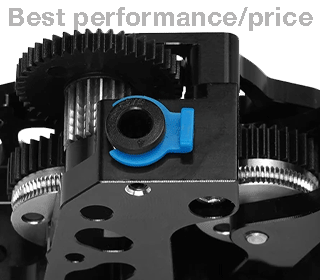

The second option is the Titan Aero direct extruder from E3D. Apparently it works well with limited issues and it has the same drawbacks for me – high price.

It is Christmas time and my wallet is getting thin. So, I went for a third option – use the stock components and build an “almost” direct extruder for Creality CR-10 at no additional cost. This article will focus on the parts needed and on testing its performance with Carbon PET, Wood and Flex filaments.

Building “almost” direct extruder with stock parts

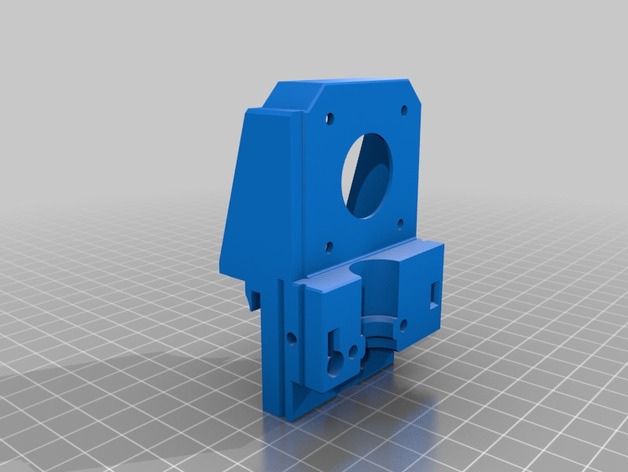

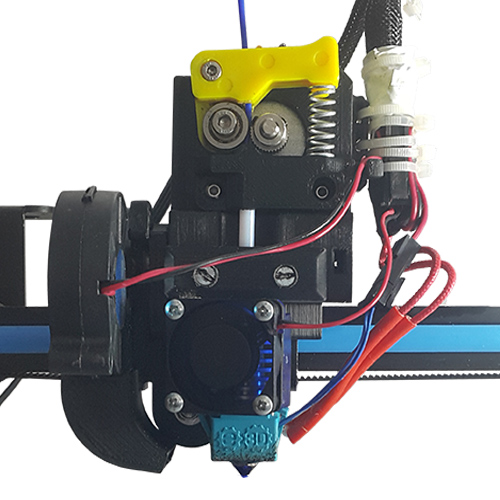

The idea is to place the stock CR-10 extruder closest possible to the hotend and almost eliminate the bowden tube. If using e3d v6 hotend there will be only 1,8 cm of tube. It should assure better extrusion pressure especially with flex.

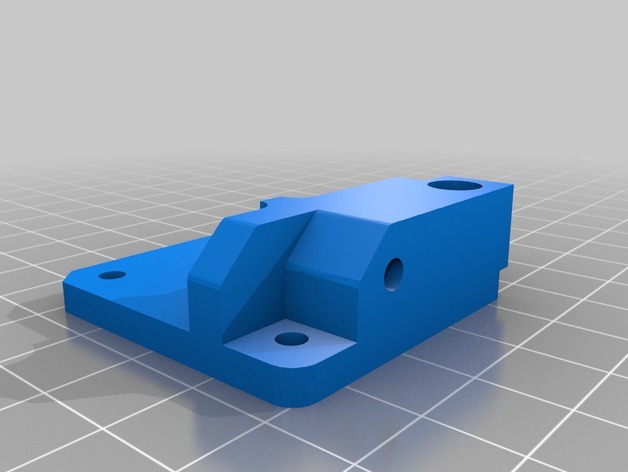

The mod is very easy and is using 3d printed parts. You will need to print an adapter plate for the extruder stepper. I printed also an improved part for the bottom of the extruder (after the drive gear), that is better designed for flex filament.

Get it from thingiverse

Get it from thingiverse

No adjustments in Merlin are needed because we’ll be using the same stepper and drive gear. Implementing the mod takes 10 min and consists in:

- Disassembly of the extruder

- Attaching the adapter plate

- Cut small Bowden tube (around 1.8 cm)

- Assembling back the extruder on the adapter plate

Test of the “almost” direct extruder

With the new direct setup I was able to 3d print all the filaments I couldn’t reliably print with the Bowden setup – Carbon PET, Wood and Flex. The disadvantage is that printing speed has to be decreased due to the much higher weight and inertia the direct extruder adds on the X-axis. It is not a big issue though, because most exotic filaments require slow speed anyway.

Here are the max. speeds I could reach for each of these filaments:

- Flex – up to 60 mm/s

- Wood filament – 40 mm/s

- Carbon PET – 60 mm/s

Final thoughts

For zero additional cost this direct setup delivers. It assured steady extruder pressure for tough and flex filaments. I didn’t have any issues so far and I wonder if I need to invest in a well engineered solution like Bondtech BMG or just to replace the heavy stock stepper with a lighter pancake stepper. What do you think?

Check also

The direct extruder mod with BMG dual drive and MGN12 linear guide.