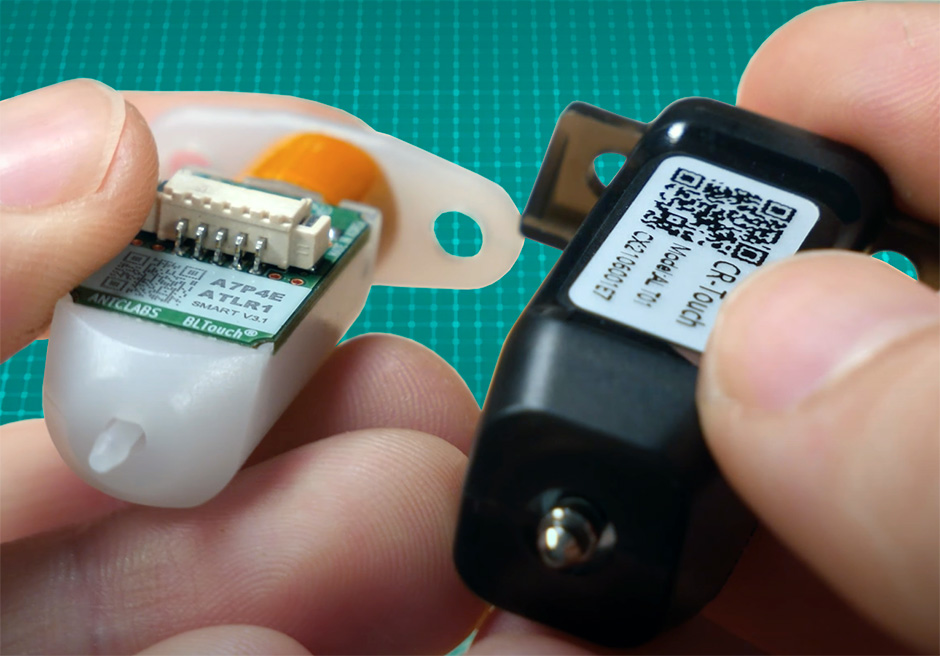

CR-Touch from Creality and BLTouch from Antclabs are ABL sensors that look similar. Both probe the bed with a pin. But is it the same technology and which one is better?

BLTouch

BLTouch has been on the market for 6+ years. It has become a very popular probe for Auto Bed Leveling because it is universal. It probes the build surface with a pushpin that is extended and retracted. As the sensing is contact-based (by touch), it doesn’t matter what the build surface type is. It works on metal, non-metal, glass, PET, martian dust, etc.

Precision (range): around 0.005 on a well-set printer

BLTouch is still one of the best ABL sensors. Wiring on modern control boards is supported and documented – either by motherboard manufactures or user communities. Installation is easy with stock or 3d printed mounts for every largely used toolhead.

BLTouch V3.1 is reliable, precise and universal sensor for ABL.

Check the current price

BLTouch – operation

But how it works? BLTouch uses a microcontroller, a Hall sensor, a solenoid switch, and a pushpin probe. It mounts on the toolhead like any other ABL sensor. The pushpin extends below the nozzle to probe the bed. When it touches the build surface it retracts and activates the hall sensor. The firmware registers the Z value at this point. Then the toolhead moves to probe the next point of the bed mesh and the solenoid valve extends again the pushpin below the nozzle.

BLTouch – precision and perturbance immunity

“BLTouch’s Standard Deviation in repeatability is around 0.005mm, at that precise.

Antclabs‘s statement on their website

Antclabs says also that this level of precision is to be expected on a well-built printer. For lower-end machines, or in case of mechanical issues like backlash, one can expect an accuracy of up to 0.05mm. This Reddit speaks about this issue and how improving the mechanics solved it.

In order to check the probe accuracy on your printer you can issue M48 command (Marlin) or Probe_Accuracy command (Klipper). If the results differ from the specs, you may want to check your printer for hidden mechanical issues.

BLTouch has good immunity to various perturbances, however, because of using a Hall sensor it is less immune to parasite magnetic fields. Though I never experienced it, other users reported abnormal readings from BLTouch probes mounted in proximity to fans or on printers equipped with magnetic beds..

CR-Touch

BLTouch has had enormous success and it has been copied by other manufacturers like 3D Touch or Artillery. When I saw CR-Touch the first time I thought it was yet another clone. But it is a slightly different product – it uses an optical sensor instead of a hall sensor to detect the end position of the pushpin.

CR-Touch operates in a similar way to BLTouch, however, the use of an optical sensor makes it immune to electromagnetic fluctuations. It can be safely mounted on printers with magnetic build platforms.

Optic sensors were introduced recently to 3d printing. Though in theory readings may be influenced by intensive light, it seems they are currently the most reliable and universal technology for ABL.

The CR-Touch comes in a nice box with mounting accessories for various types of Creality toolheads. It could replace easily BLTouch on any other existing toolhead, but you’ll need to print a new mount because the dimensions a different.

Check CR-Touch price:

CR-Touch vs. BLTouch – which touch probe to choose

Both BLTouch and CR-Touch are excellent sensors for ABL. They assure good precision accuracy of 0.005mm and reliable repeatability. User tests on different machines show slightly better repeatability for CR-Touch, but in practice it’s negligible.

CR-Touch vs. BLTouch – wiring

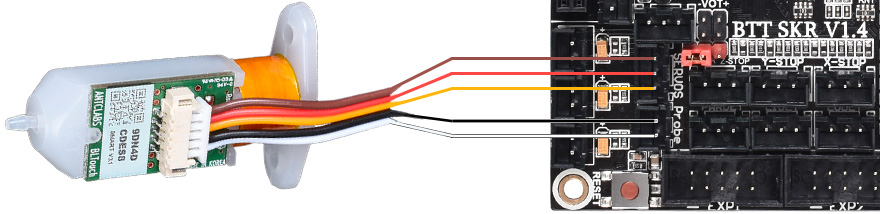

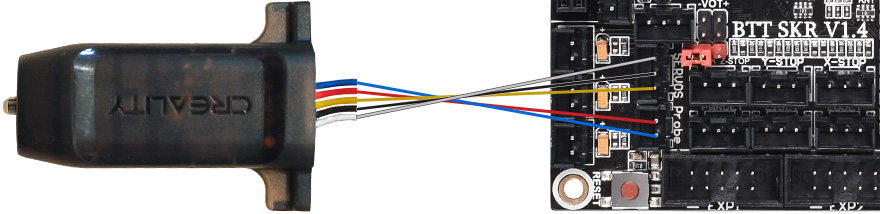

The wiring is similar for both sensors. The CR-Touch has a 5-pin connector, adapted to Creality’s newer 32-bit boards. If you implement CR-Touch on an older 3rd party board (ex. SKR 1.3/1.4), you may need to split the connector. The wiring of CR-Touch could be also a bit confusing on boards designed for BLTouch. Hereafter as an example are two wiring diagrams for SKR V1.4:

CR-Touch vs. BLTouch – design

CR-Touch seems a more robust product. It has a metal pushpin vs a polycarbonate pin on the BLTouch. But it is not necessarily an advantage. First BLTouch models also had a metal pushpin and were changed to plastic for better operation and less noise. Also, BLTouch pins are replaceable.

CR-Touch is havier with approx. 5 gr (13 gr), but both sensors are much lighter than an inductive sensor. Finally, I prefer the dark color of the CR-Touch, because it integrates better visually in the toolhead. The white BLTouch just looks like it’s not part of the same device.

Conclusion

BLTouch and CR-Touch are close price match, and deliver similar accuracy. Both are compatible with recent motherboards. If you have an Ender-3 printer with a 32-bit Creality board – go for CR-Touch, as the upgrade is straightforward. Note that you may need to upgrade the firmware.

For other printers and control boards, you can choose either. It is more of a question of a personal preference than objective performance criteria.

Check BLTouch price:

Check CR-Touch price: