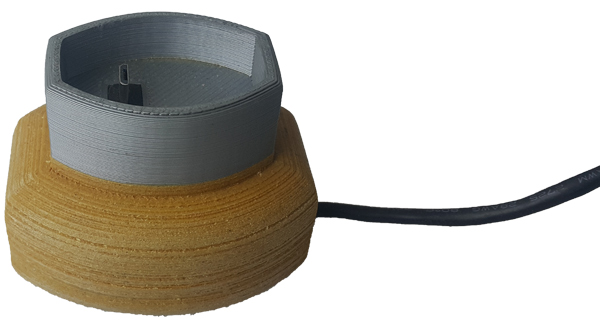

The “Original Oak” by Ice is wood filament – a composite that combines PLA and wooden particles. It gives a nice woody finish to your 3d printed parts.

One may think it should be printed as PLA, however the final settings that worked for me and allowed me to get consistent prints, were quite different.

First prints failed miserably with total clogs, either because of retraction settings or small nozzle size. On the other hand the bowden extruder setup of the CR-10 was struggling with this filament. It resulted in drive gear drops that further facilitated the clogs.

This article reviews the “Original Oak” filament and gives you tips how to print it.

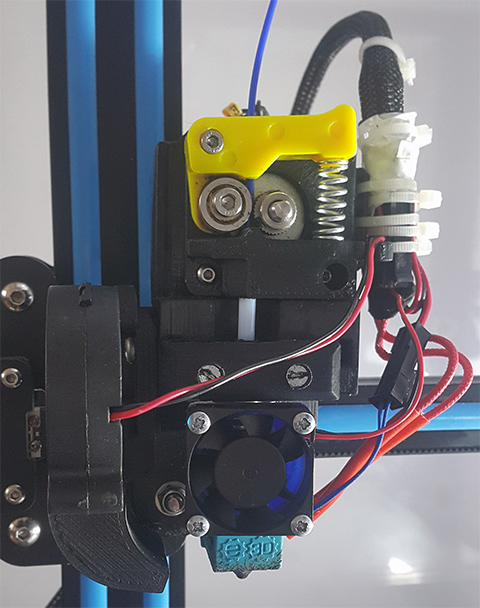

All settings are to be related to the gear used – “almost” direct extruder, 0.6 all metal nozzle (MicroSwiss), original e3d hotend, polycarbonate build surface.

The settings are good basis though for your own failure-proof set-up and successful 3d prints with wood filaments.

The filament

In Europe, you can get the “Original Oak” wood filament from Amazon ( DE, FR, UK) with a price tag around 25 EUR for 500 gr. The spool is well packaged under vacuum seal to avoid humidity. The only settings given by Ice are for the temperature: 210 to 230 °C. The filament contains real wood particles and allows some special post treatment like sanding or impregnation with wood base.

Moreover, different printing temperatures give different colouring. That may be used to achieve even nicer wooden effect and more realistic grain pattern by setting up variable layer temperatures in Simplify3D.

As the filament is PLA based, it is possible to combine it with other PLA filaments. Regular PLA sticks very well to the “Original Oak” wood filament.

It allows you to create unique designs for your 3d printed parts and models by alternating wood and other colors.

Optimal printing settings

Retraction is the most important setting in order to avoid nozzle clogs. With retraction set to 0 (zero) I could finish time demanding prints (like the Baby Groot) with no clogs. Set retraction vertical lift to 1 mm – it will decrease the stringing.

I found the best nozzle temperature is 235 °C, which is 5 °C above the maximum recommended temperature by the manufacturer.

Another very important setting is the speed. Forget about the 80 mm/s you get with regular PLA and limit the speed to 20 mm/s.

At speeds that low you dont even need cooling. Set you fan speed to zero, except for very small layers.

Finally the layer resolution should be above 0.2 mm. I print with 0.24 to 0.28 with 0.6 nozzle.

Other considerations

If you use blue tape or other standard build surface, the “Original Oak” wood filament is reported to stick well on heated bad around 60 °C. Myself I use a polycarbonate build surface and wood filaments stick well on it – no warping even if the bed is not heated.

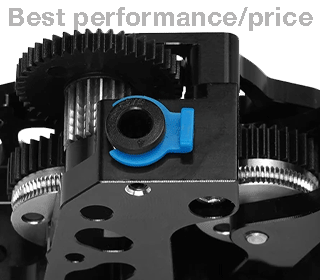

The bowden extruders on budget 3d printers like the Anet A8 or Creality CR-10 are another source of problems with flex and composite filaments like carbon, wood, aluminum or copper. Simple mods allow to convert them in “almost direct” extruders. In this way you will get more stable printing flow, however it comes with a price – you will have to print in low speed because of the higher inertia on the X-axis.