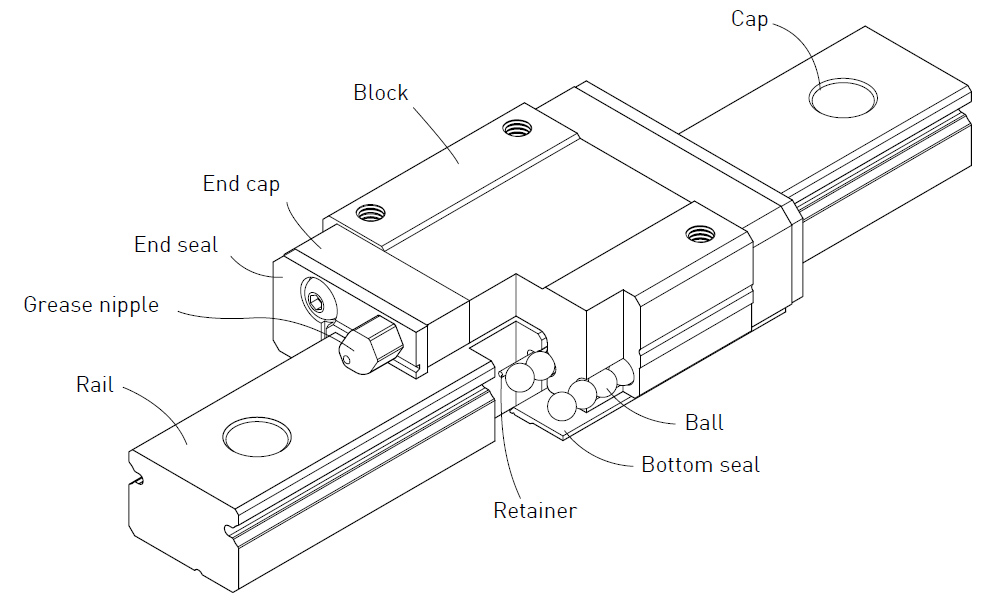

Linear guides are used for linear motion by re-circulating rolling ball elements between a profiled rail and a carriage (bearing block). The friction on a linear rail is only 2% of this of a traditional slide. Linear guides can also be loaded in all directions (no matter how you mount them). These features made the linear rails a preferred solution for high-precision CNC machines. For smaller machines like 3d printers, there are smaller and low-inertia linear rails, like the stainless steel MGN12 of Hiwin.

Using linear rail in 3d printers

The linear rails can be used on all axis of a FDM 3d printer, whatever the type – cartesian or core XY. However, the biggest impact on printing quality is achieved when the movement of the print head is improved (either the X-axis or the XY-axis).

This type of linear guides is still expensive and is only used in high-end commercial 3d printers. Enthousiast however upgrade successfuly existing printers and there are already many designs available at Thingiverse for MGN applications on low-cost popular printers, like Creality, Tevo, Anet. The rails are easy to implement, because they mount natively on the 2020 extrusion profiles of these printers.

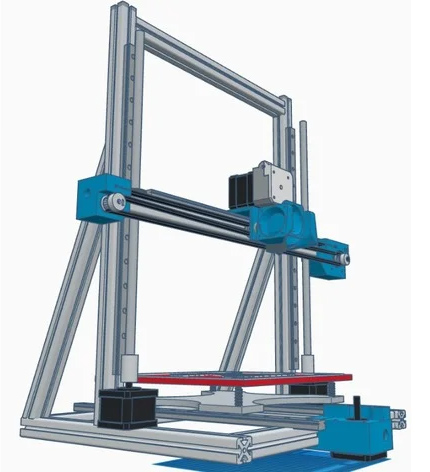

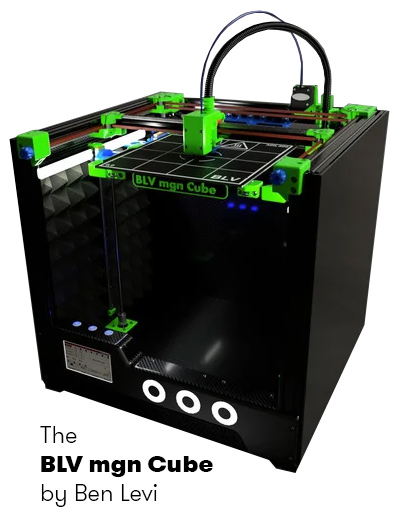

There are other more advanced designs for complete coreXY printers with linear rails. One example is the BLV printer, featuring linear rails on all axis. Its cost has dramatically improved when some companies started to offer complete kits with optimized bundle prices. Now it becomes possible to build a better mechanical solution than Ultimaker for less than 1000 USD.

Visit the page of the BLV mgn Cube on Thingiverse

Myself, I am fan of Voron Design DIY printers. They also feature linear rails on all axis and provide great performance to cost ratio.

The flagship – Voron 2.4, is amazing CoreXY machine with unique fixed bed design and gantry frame on belts.

It is fully enclosed and perfect for ABS.

The cost is about 1500 USD

Voron Zero (aka Voron0) is another printer I built. It is small, portable and energy efficient secondary machine. The linear motion uses MGN07 linear rails.

Cost: in the 600 USD

Upgrading an existing 3d printer to mgn12 linear rail

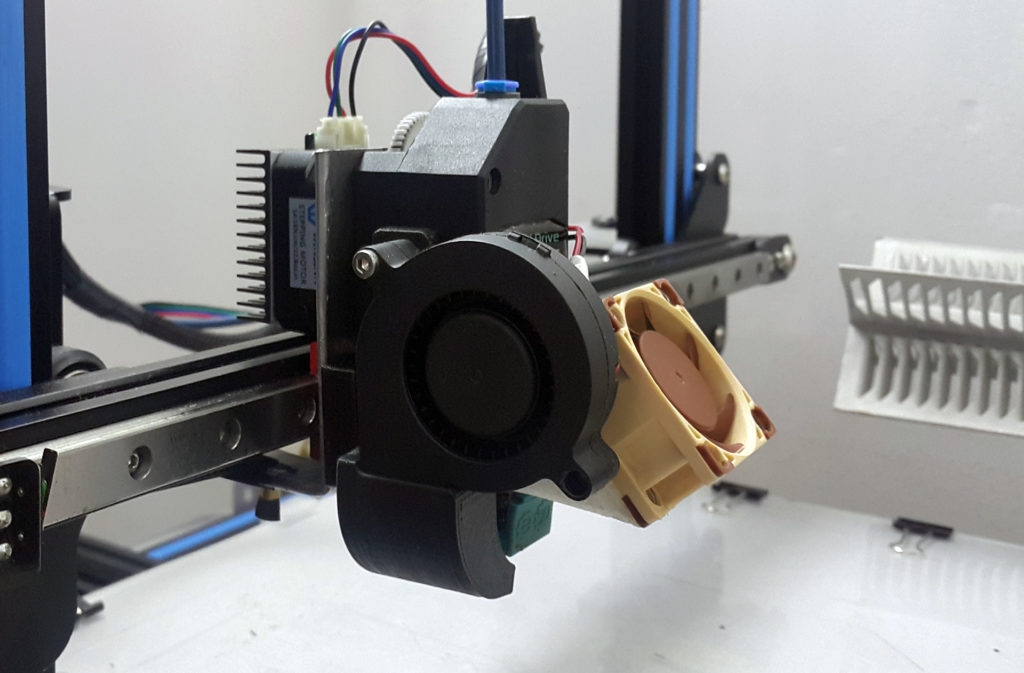

One of the main challenges when upgrading the X-axis of a 2020 extrusion based 3d printer to MGN12 linear rail is the design of the X-carriage. The new carriage should take in account the dimensions of the MGN12 rolling block and the clearance between the fixation holes. Hopefully, Hiwin offers step files to get you started.

When upgrading the X-axis of my Creality CR-10 printer to MGN12, I decided to build a carriage for light direct extruder. I made first a 3d printed model that helped me to drill and cut a metal sheet precisely.

Now I am using this print head for over a month and I can say it worth it.

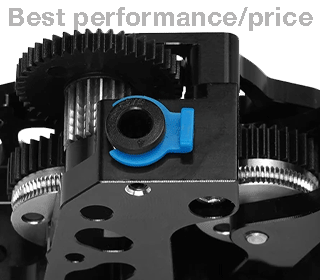

The modification is based on the BMG dual drive extruder from Trianglelab – a quality clone of the original Bondtech product.

It is a geared extruder with ratio 3:1, that delivers constant extrusion pressure wathever the filament.