The 3d printing world has become a competitive place and best-selling 3d printers bring either innovation or price optimization. The Sidewinder X2 gives you both. It is a budget large printer with a price tag of just $450. And yet it comes with modern features, a direct extruder, and AC heated bed. In this review, I will share my experience with the Artillery’s flagship – from unboxing to implementing mods.

Artillery Sidewinder X2 is selling on:

Artillery SWX2 – best-in-class features

Let’s start with what I think are the unique benefits of this printer. For its budget price, it packs all modern features, useful or useless. You’ll get a print resume after power outage, a filament runout sensor, large touch display – those are the ones I never care about. What is important for me is reliability and upgradability, which lead to better user experience and print quality. I’ll focus my review on them.

Sidewinder X2 – reliability

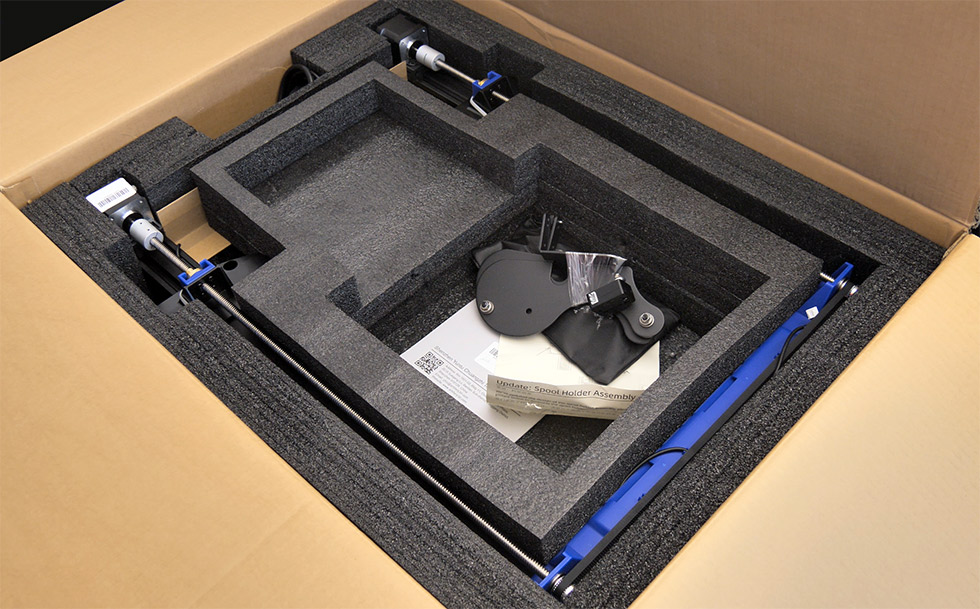

Starting from the custom packaging, Artillery made sure every piece of the printer is well protected. Chances you get a damaged printer because of handling are small. The assembly was extremely easy and error-free. All you need to do is to screw 4 bolts.

Mechanics are robust and once you check all V-wheels on the printer are rolling on the aluminum profiles, the initial setup is pretty done. Both the bed and the gantry use large 6020 profiles, which makes the V-wheels assemblies of the printhead and the build platform absolutely stable.

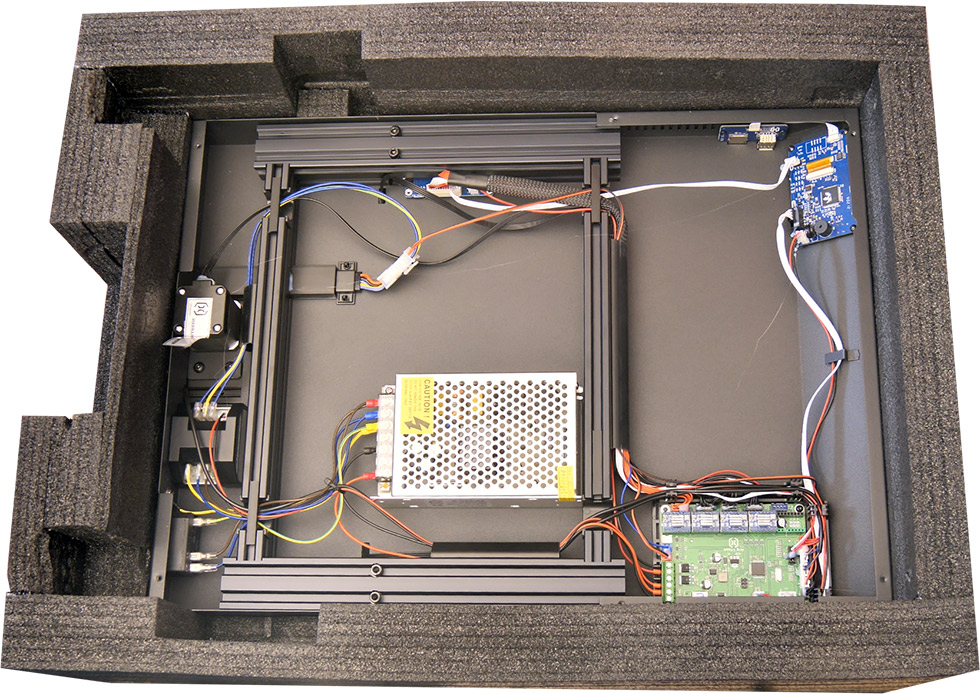

The wiring of the control compartment is very well done. I was surprised to discover how clever is the wire management. It uses dedicated pass-throughs and cuts in the base aluminum profiles. The connections are safe, using quality isolated connectors and many components are over-secured with a plastic gun.

like installing an RPi with OctoPi or control relays.

In the first 100h of printing the direct printhead and the AC heated bed performed reliably. The stock firmware seems to be set OK, I haven’t heard any skipped steps from the extruder, and the XYZ motors stayed cool. This is an open printer for PLA/PETG/TPU and so far I haven’t witnessed warping of parts. The adhesion is good. What I don’t like is that the build platform is not detachable and flexible. This is certainly something I’ll upgrade in the future.

SW-X2 – AC heat bed

One of the main selling points of the Artillery Sidewinder X2 is its AC heatbed. Like every such heater, it warms up very fast. I could reach 80 C in less than two minutes! The innovation for me though is elsewhere: Artillery applied the heater directly on tempered glass. The glass is coated on top and it is also the build surface. This concept has 2 main advantages:

- Eliminating an aluminum plate between the heating element and the build surface minimizes the weight of the build platform. This is important for such large printer and contributes to better print quality (less mass/inertia).

- The build surface is absolutely flat (glass).

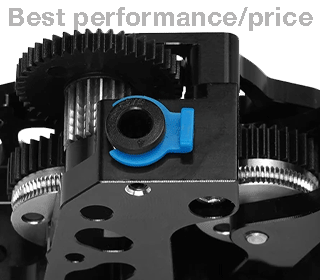

SW-X2 – Direct toolhead

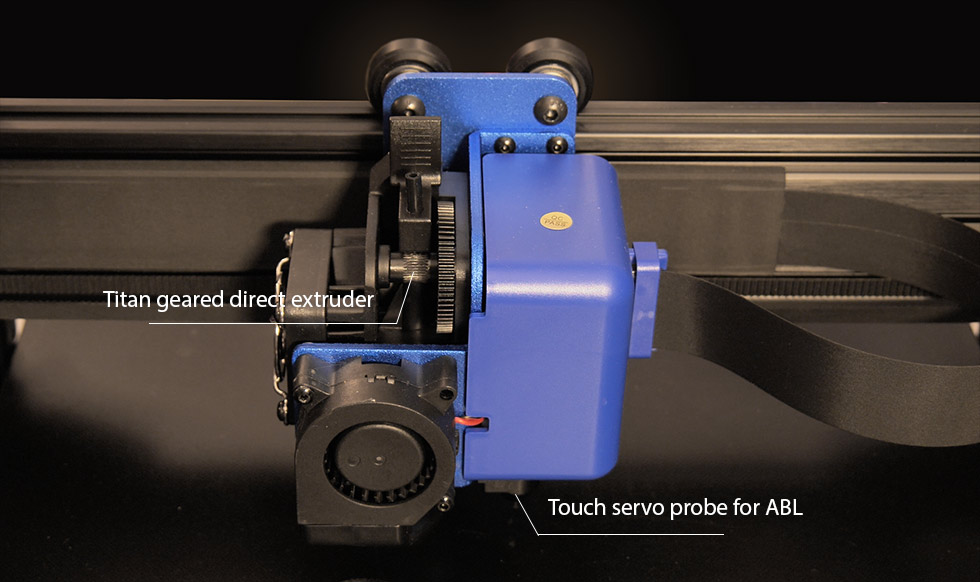

The other cool feature of the new Sidewinder is the toolhead. It is equipped with Titan type (not original E3D) direct extruder. This extruder performed very well both with flexible filament and PLA prints requiring lots of retractions.

The toolhead is equipped with a custom black Touch servo probe for Auto Bed Leveling. During my tests, it performed reliably, both for Z-offset and bed mesh.

The heat block/nozzle is Vulcano, which allows going at high speed (you could have a higher volumetric flow rate, than with a regular V6 hotend). Speed is limited though by the cooling capacity of the part cooling the 4020 blower fan. For larger parts you could test speeds up to 100mm/s, however, smaller parts will suffer poor cooling above 60mm/s.

Sidewinder X2 – upgradability

Upgrading the printer and adding new features is part of the pleasure for many makers. Out of the box the SWX2 is providing advanced components and design concepts, however enlarging the applications or improving the print quality becomes a must sooner or later, especially if it is your only printer. The good news is that you won’t be alone. The X1/X2 community is quite large and the essential mods are already on Thingiverse.

Here is my upgrades map:

- Adding Octoprint server. The SWX2 control compartment has plenty of space to add a Raspberry Pi. I added already octoprint on an old android phone with the Octo4a app (see the video above).

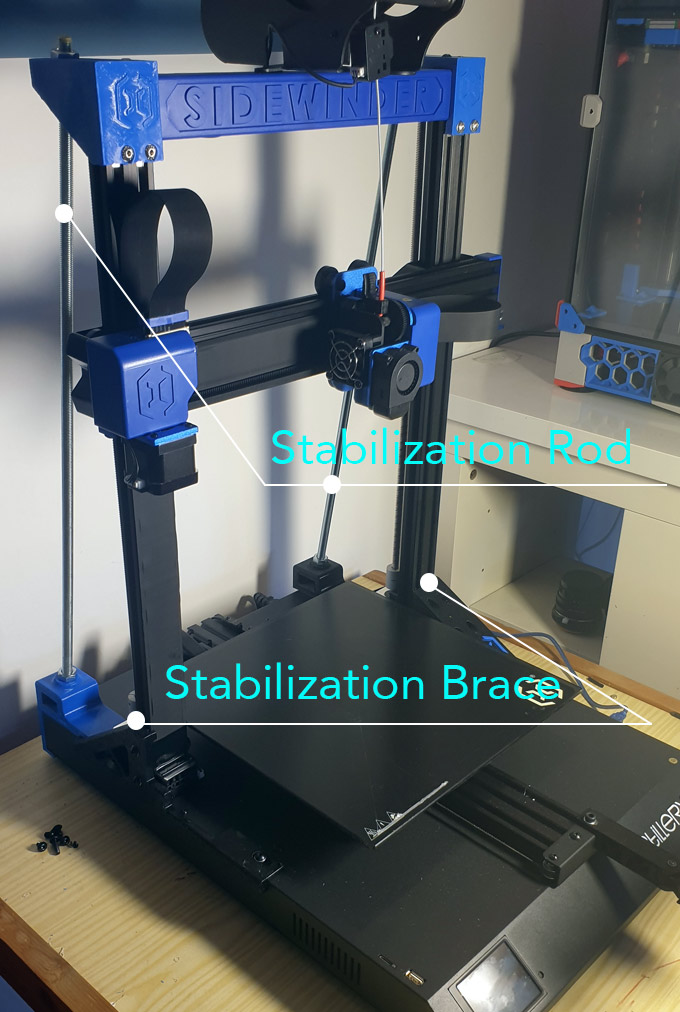

- Braces and rod stabilizers to limit the Z-wobble on tall prints. This is an essential mod to improve the quality. Z-wobble is present on all large cartesian printers with heavy direct extruders and reinforcing the frame helps to minimize the impact. Check this mod for rods and this one for braces.

- Adding PEI spring steel sheet and magnetic sticker. I wouldn’t change the AC heated bed. It is perfect. The heating element heats directly a tempered glass (no intermediary aluminum plate) and this assures the bed is absolutely flat. However, I miss a flexible platform. I believe also, printing directly on the glass may damage it if a part sticks too hard. So, I’ll most probably implement one of Energetic‘s products.

- Install Klipper. This is personal. I just like the tuning freedom of Klipper and I find Marlin the less user-friendly platform for testing and upgrading any printer.

Sidewinder X2 – print quality

Not a conclusion

Those are my first impressions and roadmap for this printer. It is certainly a great machine for the bucks. I can only recommend it to new users for its ease of assembly & setup and good printing quality out of the box. I’ll complete this article progressively with more X2 tips and findings.

Do you have a favorite mod or a useful tip for the SW X2? Share it in the comments.

ARTILLERY SW-X2

is currently selling on