The adhesion of the printed part to the hotbed is one of the most critical aspects of the 3D printing process. It depends on two major factors – good bed leveling and the properties of your build surface. This article is reviewing and tests one of the most versatile and performant build platforms – the PEI sheet.

PEI, Polyetherimide, or Ultem are all the same thing – a thermoplastic material with a very high temperature of liquid state transition (215 C) and great mechanical strength. When used for 3d printing build surface it provides reliable adhesion for most filaments and is durable. It could be used as a sticker for direct application on an aluminum hotbed or lately, the modern solution is to apply PEI folio or PEI powder coating on a spring steel sheet and use it on a magnetic hotbed.

Energetic is one of the leading companies for PEI powder coating and in this review, we will test their double-sided magnetic PEI spring steel sheet.

The best place to buy the Energetic PEI build plates is in their shop on Aliexpress.

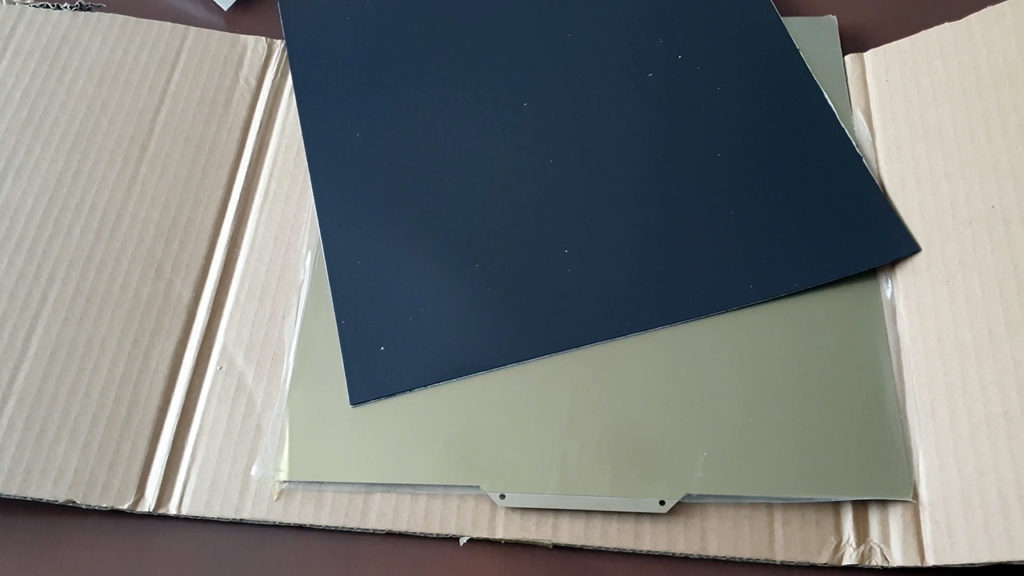

PEI spring sheet with magnetic sticker – unboxing

The PEI magnetic spring steel sheet produced by Energetic is existing in various sizes to match most of the 3d printers. The full package includes a magnetic sticker for the hotbed and a double-sided PEI spring steel sheet. There are many other variations. If you already have a magnetic hotbed, you can buy a single or double-sided PEI spring steel sheet. The PEI layer could be a folio with a smooth and flat surface or PEI powder coating with a textured surface. If you choose the Energetic double-sided PEI sheet, you’ll get one smooth and flat side with PEI folio and one textured side with powder coating.

Installation of the PEI magnetic build surface

Before installing the magnetic sticker, clean carefully the surface of your aluminum heated bed. I used 99% alcohol and a piece of cotton. A clean bed will assure better adhesion.

The installation of the magnetic sticker on the aluminum hotbed is easy – similar to installing a screen protector on your phone.

- Peel off the protective paper at one end;

- Align and fix the sticker at one end of the bed;

- Peel progressively the protective paper while chasing any air bubble with your other hand.

After the magnetic sticker is in place, you can position the PEI steel sheet over and start a print job right away. I’ll recommend though to wait a few hours, so the adhesion takes a better effect. You can even put a few heavy books on your bed.

What can you print on the Energetic PEI sheet?

PEI is performing very well as a build surface for a number of filaments – PLA, ABS, PETG, PC ABS, flexibles, etc. If you want to print PC filament though it may not be the ideal build platform, as it requires heating the bed at 125-130 C. For printing polycarbonate, we recommend using polycarbonate or polypropylene surface.

Cleaning and maintenance of your PEI spring steel sheet

PEI is a very robust material and the maintenance is limited to cleaning the surface of dust and grease. The adhesion diminishes dramatically when your sheet is dirty. Cleaning your PEI surface every few prints or after you have touched it to remove prints, will assure constant performance. The best cleaning agent is Isopropyl alcohol 91 or 99%.