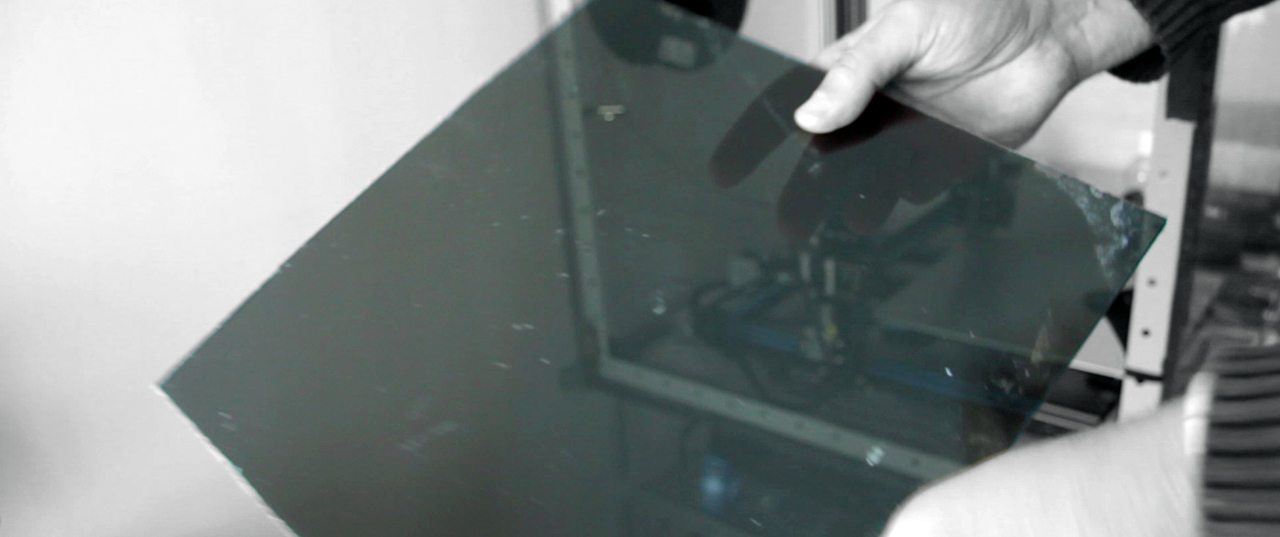

For every 3d printing hobbyist there is a stage in the learning curve when new challenges are to be taken. For me it was to print big with ABS. The discovery of the polycarbonate (Lexan) sheet build surface was one of the main milestones in this challenge.

The ABS adhere very well on the polycarbonate. The adhesion is much stronger than the relatively high warping forces due to the shrinking of the ABS when cooling down. This assures warping-free 3d printing process for big ABS prints.

Is the polycarbonate sheet only good for ABS prints? No, all type of filaments stick great on it and it became my preferred build surface for printing PLA, PETG, Flex, PC ABS, Wood, Composites PLA and Carbon PET.

Here are the main advantages of the polycarbonate build surface:

- Very good adhesion of all filaments (incliding PC filament);

- Durable – for 1 year I changed only 1 sheet;

- Quick operation – no preparation time, no tape;

- Energy efficient – no need to heat the bad to 100 °C for ABS. 80 °C just for the first 10 layers are enough;

- Low cost – a sheet of 31 x 31 cm for the CR-10 3d printer costs less than 2 EUR.