The PC filament (polycarbonate) is one of the strongests and heat resistant materials that can be thermoformed and 3d printed on a FDM printer. PC prints wont deform up to 125 ℃, which makes them perfect for functional parts. There is one small problem though – polycarbonate is difficult to print, especially on low-end budget printers.

Nozzle temperature

A pure PC filament prints at minimum nozzle temperature of 290 ℃. Lately some manufacturers started mixing some additives in their filaments in order to lower the printing temperature down to 260 ℃, however my trials and errors showed that even with these filaments the best temperature is 280+ ℃, because at lower temperatures layers dont stick well and the part is fragile.

So, here is the first challenge for a budget printer, like the CR-10 or similar. Printing PC requires upgrade of the stock nozzle (ex. e3d v6 or Mosquito) and of the bowden tube used (ex. Capricorn tube up to 300 ℃). Note that even a standard e3d v6 hotend reaches its limit at this temperature, because the e3d termistor has reliable reading up to 280 ℃. While printing at 290 ℃ is still possible, the nozzle temperature will fluctuate 4-5 ℃. The solution for reliable reading in this case is to upgrade to PT100 termocouple probe.

Heated bed temperature

Some PC filament printing reports on the net prescribe bed temperature of 135 to 150 °C using kapton tape, borosilicate glass and/or some complementary adhesives. Cheap printers normally cant go this high. How to use lower bed temperature and avoid warping? My solution was again the polycarbonate build surface. Polycarbonate on polycarbonate sticks great at just 85 °C. Check the video bellow.

Material shrinking

when cooling down

The PC shrinks when cooling down. It shrinks even more than ABS. It means that as you are printing the lower layers shrink and create forces trying to bend the part, which will result in part warping from the bed or in layer separation. For small parts these forces are small, and you can print them without enclosure. Prints bigger than 4 cm will require a heated enclosure. My tests show a stable enclosure temperature of 45-50 ℃ helps elimante the shrinking.

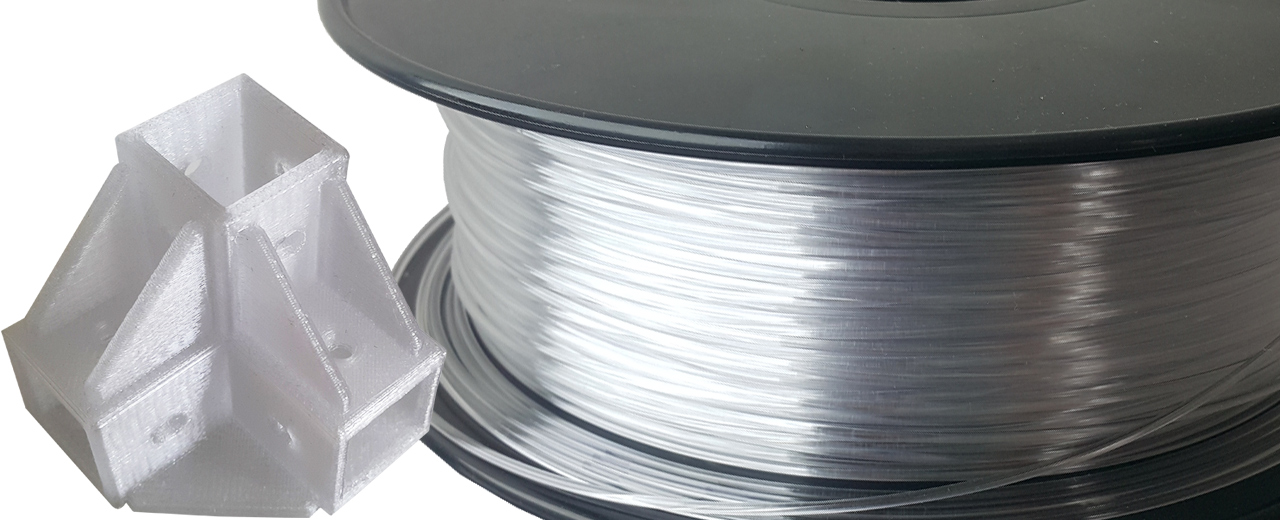

PC filament

on Amazon

PC filament

on Aliexpress

Final thoughts

Printing polycarbonate (PC) filament on one of those affordable 3d printers is possible. You need to do few modifications:

- Hotend capable of at least 290 ℃ – an e3d v6 with PT100 would be perfect, but the standard one can handle it also;

- Polycarbonate build surface;

- Heated enclosure for bigger parts.

Printing polycarbonate reminds me of printing PETG. It has similar sticky texture when extruded. In order to avoid stringing I used retraction similar to what I use for PETG (4 mm in bowden mode and just 1.5 mm in direct mode). Because minimising retraction means less chance for clogging I recomend a direct extruder. The part cooling fan should be turned off in order to avoid cooling and shrinking of the print.

The quality of your extruder is also important. You may want to check this affordable and performant extruder from Trianglelab

Last important learning point was to always tighten the nozzle when printing at very high temperatures. Otherwise you may get a leakage (check the video above).