UPDATE

There is much better and efficient build surface for ABS and all other filaments.

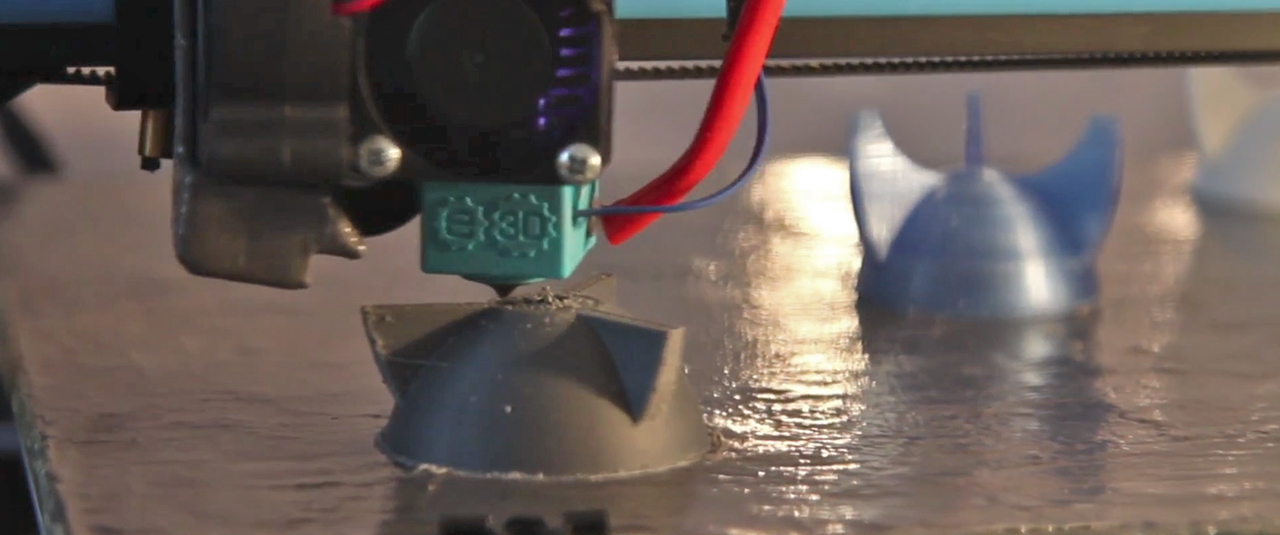

ABS is one of the most difficult to 3d print filaments. It doesn’t adhere to most common build surfaces as good as PLA and PETG, but the real problem is that the part shrinks when layers cool down. This property creates forces that try to rip off the part from the heated bed, especially when 3d printing large objects.

One solution is to print ABS into enclosure with active heating. If you can maintain a temperature of 55 – 60°C the warping forces are less strong.

Another solution is to have very strong adhesion to the bed surface.

3d printing ABS on ABS

What possibly can be better adhering then ABS to ABS? A bed surface made of ABS would the perfect one to print ABS.

This idea leaded to the DIY build surface from ABS slurry.

What is ABS slurry

It is a solution of ABS that dries fast on air. The solution is prepared with ABS (ex. leftovers of your prints) and acetone.